Underwriters Laboratories (UL) 508A is an American and Canadian standard for industrial control panels. Circuit breakers and fuses receive considerable attention as they are the first line of defense when things go wrong.

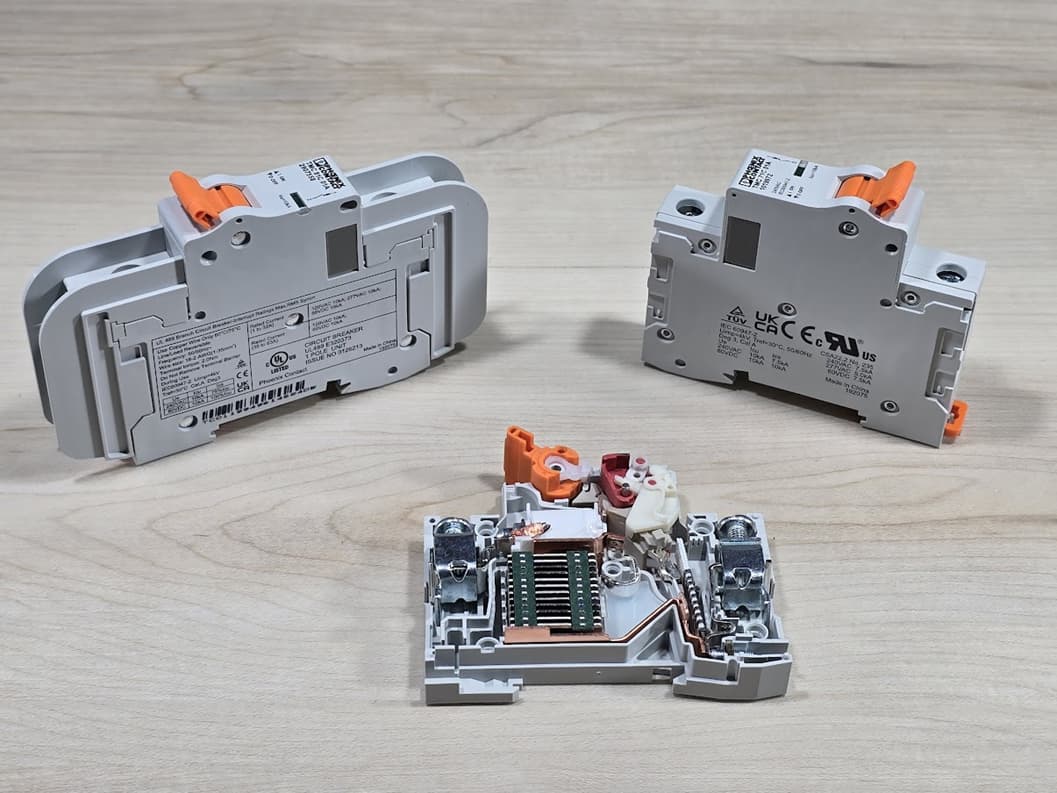

This engineering brief explores the difference between the UL listed circuit breaker and the supplementary protector. Representative examples are shown in Figure 1 including:

-

Left: Phoenix Contact TMC 81A 01A which is a UL 489 listed circuit breaker

-

Right: Phoenix Contact TMC 71C 01A which is a UL 1077 supplementary protector

Note that a partially disassembled TMC 71C 01A is shown in the foreground.

Figure 1 Phoenix Contact 2907558 circuit breaker (left) alongside a 1019972 supplementary protector (right). A partially disassembled 1019972 is shown in the foreground.

Tech Tip: Many manufacturers follow this same pattern for UL 489 and UL 1077. For example, we could have explored the Siemens 5SJ and 5SY series with similar results.

What is the relationship between the feeder and a branch circuit?

Let’s first define two terms:

-

Branch circuit: Everything downstream of the last overcurrent protective device.

-

Feeder circuit: Everything upstream of the overcurrent protective device.

A fuse or circuit breaker is installed between the feeder and each branch circuit. We could state that the circuit interrupter is the demarcation point between feeder and branch.

As an example, suppose a PLC-based control panel provides power for three motors. We can expect three sets of circuit interrupters, plus one more for the control system’s power supply. Each tap from the feeder required appropriate overcurrent protection. It’s critically important that each branch circuit protection be rated for the Short Circuit Current Ratings (SCCR) of the feeder.

Tech Tip: The SCCR is directly related to the Thevenin impedance of the feeder system. A large transformer may have a low impedance with the ability to supply 50 kA on a phase-to-phase short. We assume that a short circuit could occur after the branch circuit interrupter. Consequently, all upstream feeder fuses, circuit breakers, wire, and terminal blocks must be appropriately sized for a short circuit. Anything less could result in a panel explosion with deadly arc and blast.

Note that the UL 508A SCCR is a system-level description to ensure the integrity of the control panel. The panel must be able to handle the SCCR of the feeder. If not, an interposing isolation transformer may be required to limit the SCCR exposure of the panel.

What is the difference between UL 489 circuit breaker and UL 1077 supplementary protector?

By UL 508A definition, a UL 489 listed circuit breaker or appropriately rated fuse must be used at the demarcation point between feeder and branch. These interrupters are designed and then tested by UL to ensure the ability to withstand the stated SCCR.

Let’s stop and consider a nuanced point with regard to a UL certified panel shop. Each shop has at least one engineer or advanced technician certified as a UL Manufacturer Technical Representative (MTR). The MTR is tasked with oversight on panel design and construction to ensure compliance with the UL 508A standard. The MTR’s work is routinely verified (on-site) by a UL inspector.

As a rule, a panel carefully constructed using appropriate components may be UL listed by the MTR. Here the term “appropriate components” may include properly sized UL 489 listed breakers at that demarcation point between feeder and branch.

UL 1077 interrupters are not suitable for branch protection.

Referring back to Figure 1, we see that the TMC 71C and TMC 81C are similar. However, one is UL 489 listed and the other is UL 1077. While the TMC 81C in Figure 1 is rated for 10 kA SCCR at 277 VAC, the TMC 71C is rated for 0.2 kA according to UL 508A Table SB4.1. Installing the incorrect circuit breaker could compromise the panel’s SCCR. It will also compromise the MTR’s reputation when the UL inspector finds the discrepancy. It could also compromise the panel shop’s reputation as the panel would require rework or face loss of UL listing.

Could a UL 1077 be used in place of a UL 489 circuit breaker.

As I understand the UL standard, theoretically yes, BUT! The panel would need to be physically tested to make that determination. All things considered, it would be less costly to stick to the established UL listed product and the MTR program guidelines.

How can I determine if a circuit breaker is UL 489 listed?

Manufacturers dedicate a significant amount of effort to ensure UL compliance. Consequently, they will not be shy about displaying the UL markings.

The Phoenix Contact 2907558 is shown in Figure 2. Here we see a prominent UL circle along with the word LISTED. The UL 489 appears as the very first word in the label. While it’s subtle, the UL file number E320373 also appears. This number points to an official, highly detailed document describing the test conditions for the circuit breaker. It also allows us to quickly find the information in UL’s Product iQ.

On a related note, Figure 3 shows the UL recognized marking (backward UR symbol) for the Phoenix Contact 1019972 supplementary protector.

Figure 2: Image of the Phoenix Contact 2907558 circuit breaker showing the UL E320373 Listing.

Figure 3: Image of the Phoenix Contact 1019972 supplementary protector with the UL Recognized Component Mark.

Parting thoughts

The Phoenix Contact TMC 81A circuit breaker and TMC 71C supplementary protector look almost identical. Yet, they are handled very differently in a UL 508A panel shop context. Be mindful of the difference and select the TMC 81A for high SCCR branch protection.

All are quality products suitable for their niche applications. However, for UL 508A branch protection, we select the UL489 listed circuit breaker.

Best wishes,

APDahlen

Related information

Please follow these links to related and useful information:

About this author

Aaron Dahlen, LCDR USCG (Ret.), serves as an application engineer at DigiKey. He has a unique electronics and automation foundation built over a 27-year military career as a technician and engineer which was further enhanced by 12 years of teaching (interwoven). With an MSEE degree from Minnesota State University, Mankato, Dahlen has taught in an ABET-accredited EE program, served as the program coordinator for an EET program, and taught component-level repair to military electronics technicians. Dahlen has returned to his Northern Minnesota home and thoroughly enjoys researching and writing articles such as this.