I joined an interesting webinar yesterday on TE Connectivity’s new ECONIDUR plating process, and true to my personal form, it sent me on a deep dive into the world of connector contacts.

For the better part of a decade, I treated gold contacts as quite literally “the gold standard” – it had better conductivity, resisted corrosion, offered low mating friction and held up well in demanding environments like those with vibration. I was like goldmember: the more gold, the better.

… So what’s the problem with gold?

But this gold comes at a cost: literally in the cost of the contact but also in the form as costs to the environment. Gold is difficult to mine and it leaves a massive carbon footprint.

Let’s paint a comparison of gold versus another similar metal: silver. Harvesting a ton of silver produces 125 tons of CO₂ and 250 MWh of energy. You would think gold would be similar, right? Nope. Extracting a ton of gold produces 72 times more more CO₂ and 80 times more energy (9,000 tons of CO₂ and 20 thousand MWh of energy respectively) (Bellefontaine, 2025). Unfortunately silver isn’t as optimal as gold for contacts (it’s prone to oxidation), hence the search for better alternatives.

So why not scale back on gold and leave it to a thin coating on the base material? A simply thin gold flashing by itself on the core conductor can wear off during connector mating cycles, meaning the base material can be left exposed and at risk of corrosion or signal loss. Understandably so, this means that in harsh environments where those connectors are going through high mating cycles, vibration or with humidity, those connector contacts are at high risk.

That leaves the electronics industry at a crossroad: design with ample amounts of gold to maintain system signal integrity, or forgo gold and compromise the interconnect design. BUT - there’s another option to consider…

So what does a solution look like?

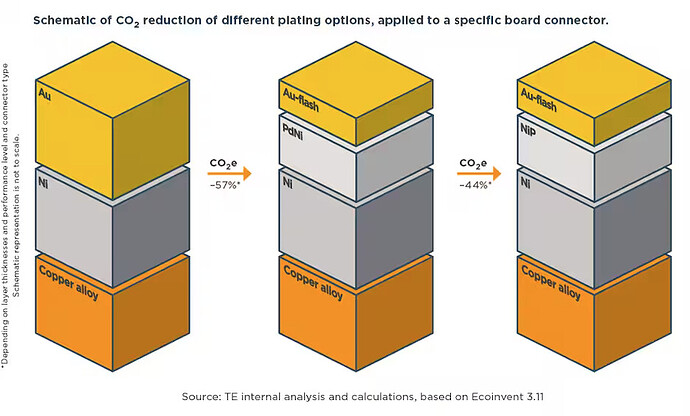

When it comes to contacts, it’s crucial to maintain properties that allow those connector contacts the ability to resist corrosion or signal loss. TE’s ECONIDUR is a technology introduction on how it approaches making contacts without sacrificing the environment.

- The contact surface layer is composed of two metals: a gold flashing (AU) plus nickel phosphorus (NIP) - this layer is responsible for protection against corrosion, provides the low mating friction, and can handle vibration situations.

- The intermediate layer of nickel acts as a diffusion barrier and absorbs stress to interface between contact surface and base material layer.

- Lastly, the base material of copper provides high electrical and thermal conductivity.

By going from a pure gold contact to the ECONIDUR design, TE’s internal assessments and calculations showed a possible CO2 reduction of up to 76%. Of course, actual environmental impact may vary based on your specific application and their conditions and depending on factors like plating thickness, connector type, pin count etc.

Conclusion

In the end, ECONIDUR plating shows that high-performance electrical contacts don’t have to come at the expense of environmental responsibility. By rethinking the material stack and strategically minimizing gold usage, TE demonstrates that engineers can preserve the reliability, conductivity, and durability they expect while dramatically reducing the carbon burden traditionally associated with gold plating. As sustainability pressures rise and design teams look for ways to balance performance with stewardship, innovations like ECONIDUR point toward a future where “the gold standard” is defined not just by technical excellence, but by smarter, cleaner choices in how those materials are used.

Resources

Bellefontaine, R. (2025, April 25). Charted: The costs of mining silver vs. gold. Visual Capitalist. https://www.visualcapitalist.com/sp/the-costs-of-mining-silver-vs-gold/

EAO. (2024, December 16). Benefits of gold-plated vs. silver contacts. Digi-Key. https://www.digikey.com/en/blog/benefits-of-gold-plated-vs-silver-contacts

TE Connectivity. (n.d.). ECONIDUR plating. TE Connectivity. https://www.te.com/en/products/connectors/intersection/econidur-plating.html