I’m just wondering if I could get a little help selecting a couple of components please.

What I’m trying to achieve:

Scenario 1:

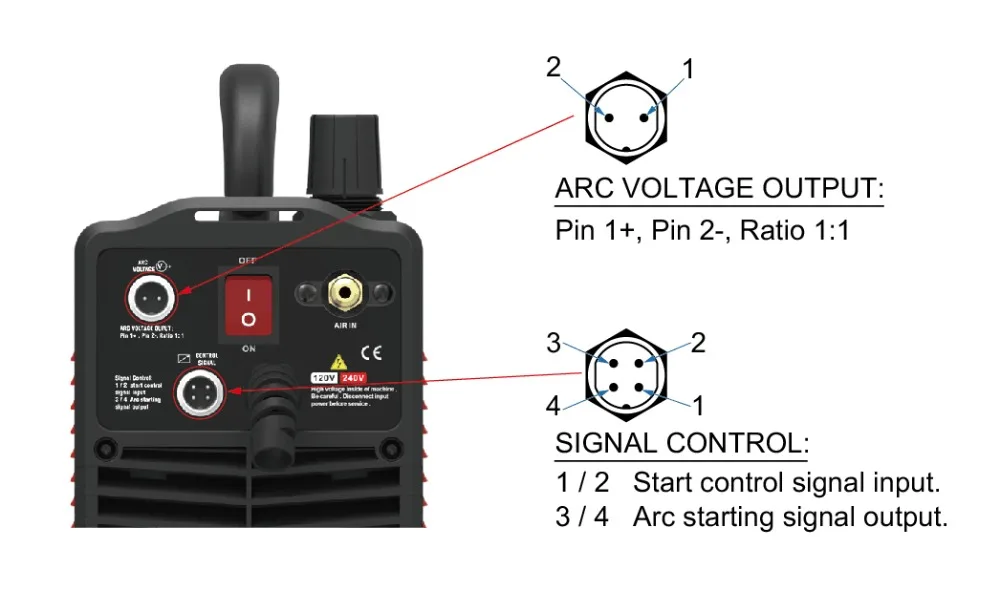

Voltage divider to act as a bridge between the cnc port on my plasma cutter and an arduino to control this. I understand the voltage ranges from the plasma cutter will be somewhere between 100-200v, and I need to step this down to somewhere between 5-12v so my arduino can read this without frying it, to act as a torch height controller.

The plasma unit itself can put out upto 45-55A, but would normally be around 30-40A, however I’m unsure if it would put this amperage out through the CNC port.

What would be a product could achieve this ?

I understand that something like this component below might be suitable if it wasn’t for the amperage requirement: https://www.digikey.com.au/product-detail/en/linear-technology-analog-devices/LT8315EFE-PBF/LT8315EFE-PBF-ND/6670433

It is suitable for DC output or only AC ? (Plasma Cutter is inverter DC)

Scenario 2 (Separate project):

I’m linking lithium ion batteries together in series and then in parallel, up-to a dc motor.

Being Li-Ion I would like to add additional protection so no / little current flows back into the batteries to create a short, especially being hooked up to a motor and and another parallel pack.

I will be adding 2x 20.2v lithium packs together to make a 40.4v pack, then i will be linking this up in parallel with an identical pack to form a ‘power rail’ that both of the dc motors can feed off to ensure it is always supplying the same current and voltage to both motors.

Each battery pack is capable of supplying 15A, so there will be about a 30A capacity flowing through the power rail at 40.4v (which will feed into a step down converter to tune it down to 36v for the motor).

Would this product suit this requirement? https://www.digikey.com.au/product-detail/en/stmicroelectronics/FERD40H100STS/497-16954-ND/6166879

Would there be any other considerations I would need to take into account for this scenario?

Are the diodes in the right spots / required in each segment?

I appreciate your help in advance.