The finger vs hand designation for light curtains is primarily defined by beam spacing:

- Finger implies close beam spacing (approximately 14 mm)

- Hand implies wider beam spacing (approximately 30 mm)

This is a critical safety distinction as it determines how far a person may insert their hands into the machinery before triggering an emergency shutdown. A finger-designated light curtain will provide a faster (more sensitive) detection but has a greater cost as more beams (emitters and receivers) are used per linear foot of light curtain protection.

![]() Canonical Article: Engineering Guide for Light Curtains

Canonical Article: Engineering Guide for Light Curtains

Illustration

We illustrate beam distance using Figures 1 through 3:

-

In the first image, we see the close-up of a SICK light curtain. The individual beam lenses are clearly visible, allowing us to measure the distance between parallel beams

-

The second image shows a comparison between the author’s hand and a caliper set to 30 mm. The author has relatively large hands with 30 mm at the knuckle.

-

The third image shows the author’s finger as compared to a caliper set to 14 mm.

Figure 1: Close-up image of a SICK light curtain showing the individual lenses with 30 mm spacing.

Figure 2: Author’s knuckles as compared to a 30 mm gauge.

Figure 3: Author’s finger as compared to a 14 mm gauge.

Why beam distance matters for light curtain safety

In this example, the author could insert his hand up to the knuckle before triggering an emergency stop. A smaller person, or child visiting your facility, may be able to reach all the way to the wrist or even forearm before triggering the emergency stop. This is an important safety consideration as we need to protect everyone, not just the (mostly) predictable operator and technicians.

At this point we have two options:

-

Increase the distance between the light curtain and the hazardous equipment (increase the machine’s footprint).

-

We reduce the beam distance from the light sensor and use a finger-safe device.

Both options are valid provided a proper safety analysis is conducted to determine the clearances.

Tech Tip: It’s not enough to simply install a light curtain and safety relay on your equipment. For example, suppose the light curtain is protecting a high-inertia saw. A proper safety analysis would identify the hazard to life and limb.

- Mechanical guarding may be required

- The distance between light curtain and saw is a critical variable

- Other equipment such as a saw brake may be required

Consult a safety engineer and codes such as ISO 13855:2024.

Use DigiKey selection tools to compare finger vs hand designated light curtains

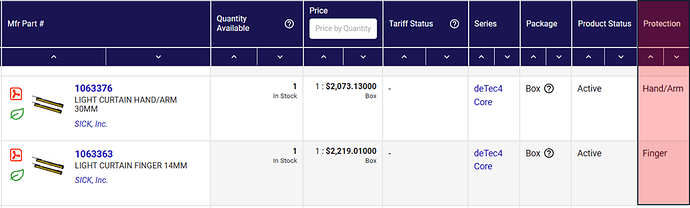

DigiKey’s parametric search engine classifies a light curtain as either “Hand/Arm” or “Finger” as highlighted in Figure 4. To understand the distinction, we will perform a case study using representative SICK light curtains, including:

-

Finger designated SICK 1063363

-

Hand designated SICK 1063376

Differential comparison between a finger and hand designate light curtain

To better understand the distinction, we use DigiKey’s compare function and then select for fields that are different between the two curtains. As shown in Figure 5.

Figure 4: DigiKey parameters for SICK light curtains with the protection field highlighted. Prices are accurate as of July 10, 2025 but are subject to change. Please follow the previously mentioned product links for the latest price.

Figure 5: DigiKey product comparison (delta) between the finger and hand designated light curtains.

Observations

-

The beam distance metric is located in several places:

- 14 mm for finger

- 30 mm for hand

-

The finger protection light curtain is slightly more expensive. This is natural as there are more beams for a given light curtain length.

-

The valid sensing distance is reduced. Even with quality lenses (Figure 1), the light will spread. Beam separation is vital for this SICK deTECH light curtain.

![]() Article by Aaron Dahlen, LCDR USCG (Ret.), Application Engineer at DigiKey

Article by Aaron Dahlen, LCDR USCG (Ret.), Application Engineer at DigiKey