We use these PTC chips B59102R270A10 as heating elements for a “self-regulating” heater.

We place these PTC chips between 2 metal conductor plates (with wires crimped onto the ends), place a thin metal cover overtop, and then swege the unit to secure the wire connections and form the shape.

Does the amount of compression the PTC chip undergoes impact its temperature-dependent resistive behavior? Some heaters heat much more aggressively than others, despite being connected to the same power supply.

Is this normal variability in this component or does compression impact the temperature-dependent resistive behavior of this component?

Does this component act like other PTC’s and open the circuit at a certain temperature? And then retain its shape as temperature decreases again?

Would compressing this chip within the metal plates make it harder for the necessary deformation to occur, and thus continue to dissipate power past the max temp?

Greetings,

I don’t think I’ve run across a device quite of that sort before…

Invoking familiarity with other devices of the class to offer a response your questions (to be taken with salt) I’d point first of all to that ±50% tolerance on base resistance. That’s a level of variability that a person can pick up on casually without much in the way of instrumentation.

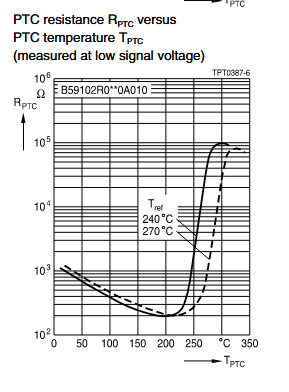

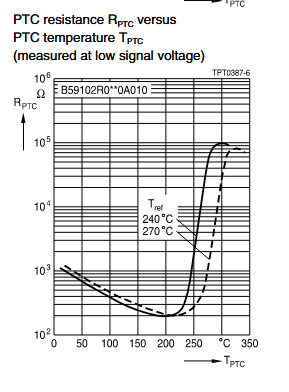

I’d then point to the characteristic curve for the device given in the datasheet.

Stare at that for a bit, and you’ll start to see that the whole “positive temperature coefficient” thing doesn’t really apply until the device goes north of ~200°C. Up to that point, the tempco is actually negative, and rather strongly so. The effect of that would be to amplify the already-large variability among devices in terms of power dissipation in situations where there’s good thermal contact and a large thermal mass being brought to temperature.

Those variations all get swamped out by the factor-of-100 increase in resistance over baseline that occurs between about 270 and 325°C though, so while the temperature to which one device will regulate might be fairly consistent from one device to the next, the rate at which one device will deliver energy in the course of reaching that destination can vary by a socially-awkward amount.

I can’t speak to the influence of mechanical factors, but the the behavior of the device is non-intuitive enough that I wouldn’t start barking up that tree prior to quantifying the performance of the device in-situ.