What is a shunt trip circuit breaker?

The shunt trip is an electromechanical device designed to trip a circuit breaker. This auxiliary device is added to, or integrated into, a circuit breaker’s body. The solenoid-like mechanism is then electrically activated to trip the circuit breaker.

A representative example is shown in Figure 1 where the Phoenix Contact 2908222 is clipped to the side of a TMC 71C 01A supplementary protector.

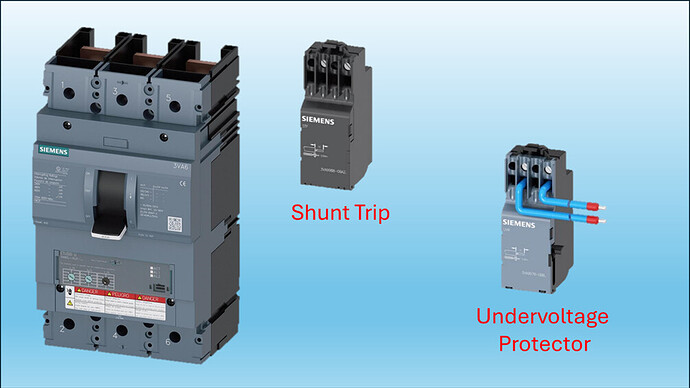

Note that Figure 1 showcases one of the smallest shunt trip combinations available. At the other end of the spectrum are large three-phase devices such as the 400A Siemens 3VA63405HL310AA0 as shown in Figure 2. The 120 VAC 3VA99780BA22 shunt trip module is also shown in the image.

Figure 1: Image of the side-mounted shunt trip and the Phoenix Contact TMC 71C supplementary protector. The circuit breaker is shown in the trip (off) position. The red flag indicates that the shunt trip was activated.

Tech Tip: The shunt trip mechanism must be tested as part of the equipment’s routine preventative maintenance. This provides a high level of confidence that the system will work when called upon.

Figure 2: Large Siemens circuit breaker shown alongside the shunt trip and undervoltage protector modules.

Advantages of the shunt trip circuit breaker in industrial applications

The shunt trip circuit breaker can be an integral part of your plant’s safety. The greatest benefit is that a shunt trip circuit breaker requires a manual reset. This gives the technician the opportunity to survey the situation, talk to the equipment operator, and take appropriate action.

There is something to be said for the simplicity of the shunt trip. Since the shunt trip operates directly on the circuit breaker, it can interrupt the fully loaded current of the machine. It does so with an independent and isolated two-wire interface. A variety of shunt trip voltages are available to accommodate common voltages such as 24 VDC, 120, 208, 277, and 480 VAC.

Tech Tip: When we consider real-world control and safety philosophy, we are forced to recognize the subtle but important distinction between a routine (controlled) equipment stop and an immediate emergency stop. There are situations when an emergency stop will trip the primary circuit breaker. There are also situations when emergency remote equipment trip is appropriate.

Risk analysis and UL 508A code compliance are beyond the scope of this article.

Disadvantages of a shunt trip circuit breaker in industrial applications

The Phoenix Contact breaker shown in Figure 1 has a red visible flag indicating that the shunt trip has been activated. However, this useful function is not universally available. This can lead to subtle ambiguity problems as it is difficult to differentiate a shunt trip from an overcurrent fault trip. This can consume considerable troubleshooting time as the technician attempts to sleuth the root cause. There can be mitigated with PLC detection and logging of the shunt trip event.

Also, most shunt trip breakers are activated by applying a control voltage. Consequently, they are susceptible to broken wire failures.

As a related example, consider the inhibitory signals derived from pushbuttons designed to stop the equipment. In most cases, these are wired with normally closed contacts so that a broken wire will immediately shut down the equipment. This is a classic fail-safe philosophy where common failures cause the equipment to shut down. By contrast, we would never wire a start pushbutton with a normally closed contact.

For compliance with this fail-safe logic, the shunt trip would be designed to trip on loss of control signal. This would ensure that a broken wire or loss of controlling power supply would inhibit the machine. Unfortunately, this default-trip safety mechanism is rarely encountered. This is likely due to the high power consumption required to continually hold a spring-loaded mechanism.

Tech Tip: The failsafe-trip-upon-loss of control voltage option is available for many of the larger circuit breakers. For example, the previously mentioned Siemens breaker may be optionally equipped with the 3VA99780BB24 undervoltage protector.

Can the shunt trip circuit be self-powered?

In this case the term “self-powered” implies that the trip voltage is derived from the circuit breaker being tripped. Yes, this can be done as the breaker should be well on its way to being tripped (open) before the shunt trip voltage is lost.

However, we would need to do a full risk assessment to determine if this is a reasonable and safe operation. Once again, we find ourselves embroiled in the design philosophy. There is a guiding principle that states that a machine operation should be predictable and consistent under all conditions.

As a counter example, consider a poorly designed machine with a poorly integrated shunt trip. Now consider this chain of unfortunate events:

- The plant has lost commercial power.

- The plant’s backup 750 kVA generator is in the process of starting and stabilizing.

- The operator presses the emergency stop button expecting to trip the machine’s circuit breaker.

- The operator resets the emergency stop actuator.

- The backup generator circuit breaker closes restoring power to the plant.

- The equipment springs to life causing damage to property and limb.

In this situation an undervoltage protector may have been a better option than the shunt trip as it would ensure the breaker trips upon loss of power.

Common shunt trip circuit breaker issues

This section contains a list of problems that we may encounter when using a shunt trip circuit breaker in industrial applications.

Incorrect voltage

Shunt trips are available for common control voltages such as 24 VDC, 120, 208, 277, and 480 VAC. The repair technician must verify the coil voltage for the shunt trip accessory. Improper installation could result in failure to trip (due to undervoltage) or destruction of the shunt trip coil.

Attempt to reset while the shunt voltage is still applied

You will only make this mistake once!

If the shunt power is still applied, the breaker will immediately trip. This can be startling experience as the spring tension is suddenly removed or the mechanism may spring back into your hand. Remember to use one hand and turn your head away from the breaker to minimize risk.

Hazard from external sources of power

The shunt trip may be powered from a source of power external to the control panel.

In an ideal world, the control panel is clearly labeled and color-coded to indicate the presence of external sources of power. This is not always the case. Consequently, technicians should always take proper precautions when the panel is exposed. Be sure to identify this situation and properly identify equipment groupings for the Lock Out Tag Out (LOTO) documentation.

Broken wires and other damage to control circuitry

This hazard is important enough to repeat. The shunt trip is not intrinsically fail-safe. Therefore, it is critical to routinely test the unit. For critical applications with larger circuit breakers, the undervoltage protector may be appropriate.

Ambiguous trip

It can be difficult to differentiate between a shunt trip emergency stop and an overcurrent fault. It takes an attentive technician to discover the difference and take appropriate action.

Overheating of the shunt trip solenoid

The shunt trip is an intermittent event that takes a fraction of a second. If the shunt trip is self-powered, the event will be very short. However, if the shunt trip is externally powered, the coil could be energized for an extended period of time causing overheating. As an example, consider the consequences when an operator performs an inappropriate shutdown prior to departing for a long weekend. Be sure to verify the duty cycle recommendations from the device datasheet.

Parting thoughts

The shunt trip and undervoltage protectors are useful circuit breaker accessories. Be sure to perform a risk assessment to determine if they should be incorporated into your plant’s safety systems.

Please leave your comments and suggestions in the space below.

Best wishes,

APDahlen

Related information

Please follow these links to related and useful information:

About this author

Aaron Dahlen, LCDR USCG (Ret.), serves as an application engineer at DigiKey. He has a unique electronics and automation foundation built over a 27-year military career as a technician and engineer which was further enhanced by 12 years of teaching (interwoven). With an MSEE degree from Minnesota State University, Mankato, Dahlen has taught in an ABET-accredited EE program, served as the program coordinator for an EET program, and taught component-level repair to military electronics technicians. Dahlen has returned to his Northern Minnesota home and thoroughly enjoys researching and writing articles such as this.